11 Describe the Terminology Used for the Appropriate Welding Positions

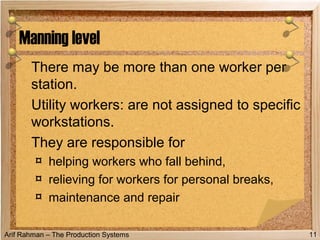

Flat PA Horizontal vertical PB Horizontal PC Vertical upwards PF Vertical downwards PG 113 Use appropriate methods and equipment to check the quality and check that all dimensional and geometrical aspects of the weld are to the specification. ConTinued on Page 9.

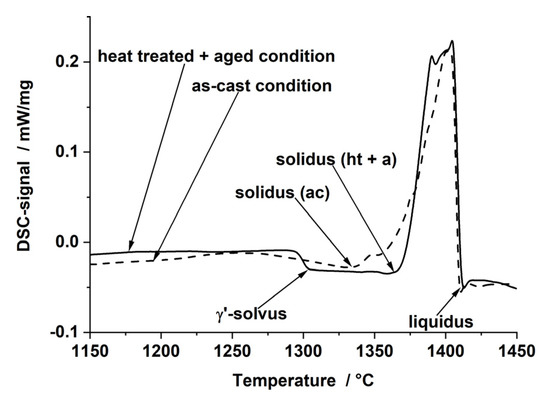

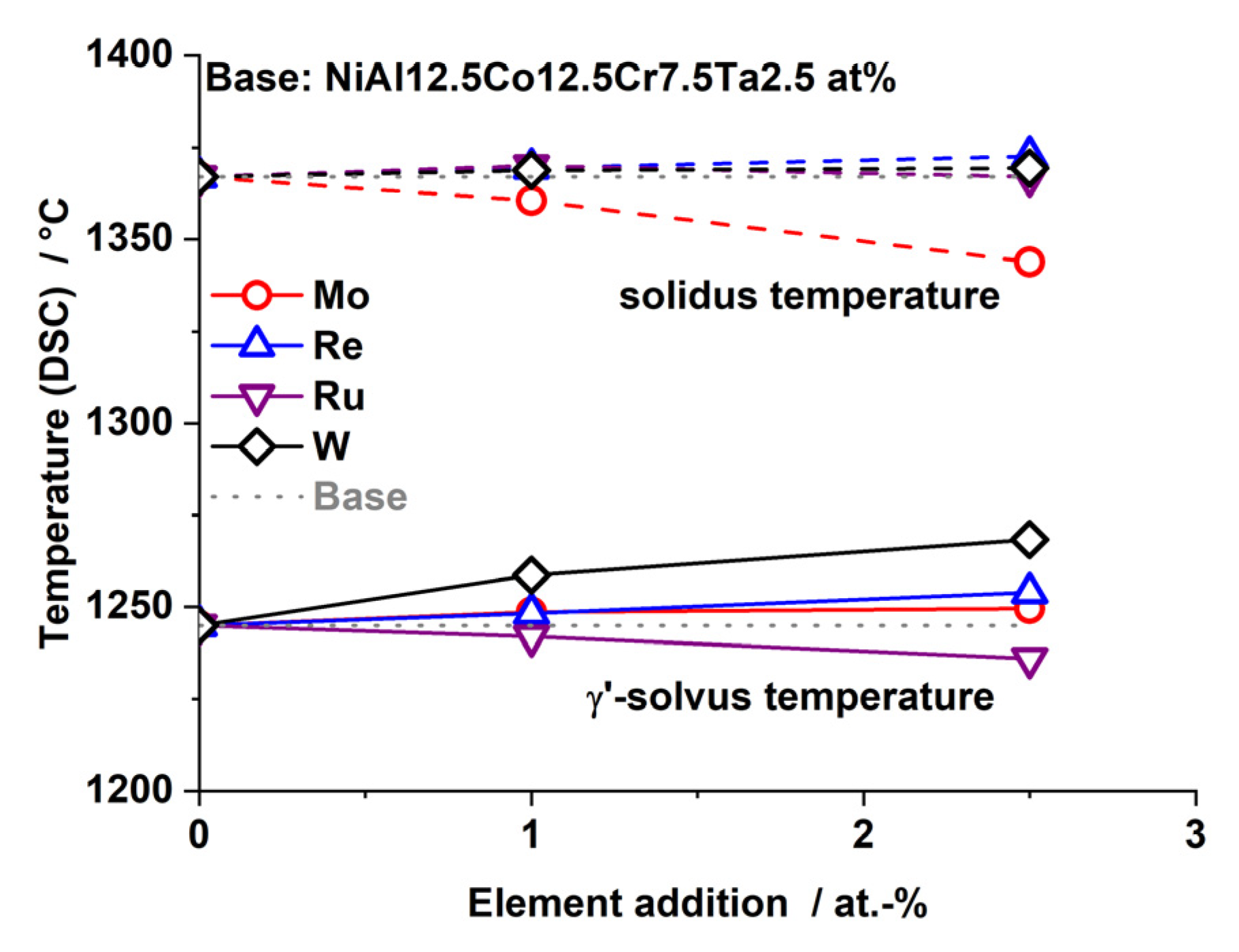

Metals Free Full Text Improving The Effectiveness Of The Solid Solution Strengthening Elements Mo Re Ru And W In Single Crystalline Nickel Based Superalloys Html

Overhead positions to American Welding Society AWS and industry standards.

. Overhead 4F For Groove welds following are the welding positions defined. The welding positions shown above are commonly used by codes whenqualifying welders. Not every welding project is the same so its important to ensure the right weld is used each time.

Annealing is the slow cooling of the metal to reduce internal stresses make the material softer and change ductility among other things. Here at Arc Welding Services we decided to run you through the main four welding positions in most applications ranging from least to most complex. To get you started heres a compilation of the most commonly used welding terms.

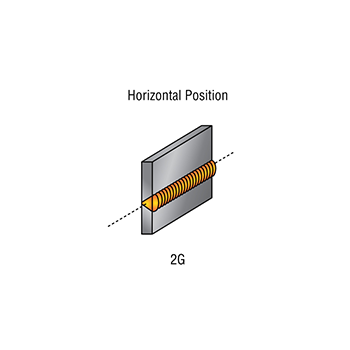

Weld joints in good access situations in two of the following EN ISO 6947 positions. Figure 11 shows the terminology used to describe the various parts of the weld. Overhead 4F For Groove welds following are the welding positions defined.

For Fillet welds following are the welding positions defined. Describe the terminology used for the appropriate welding positions Answer- The correct terminology for welding positions such include PA PB PF and PG PA meaning the flat position PB is horizontal position PF perpendicular uphill PG perpendicular downhill. NOCTI Job Ready Assessment Page 11.

Weaving a side to side motion for wider welds. Page 10 of 11 Sample Job Welding. They use arbitrary numbers to indicate position of the weld from 1 flat to 4 overhead.

WELDING TECHNOLOGYDOCX PAGE 5 BALDY VIEW REGIONAL OCCUPATIONAL PROGRAM Anchor Standards 20 Communications. Demonstrate appropriate use of arc cutting equipment Shielded Metal Arc Welding SMAW. Welding equiPmenT 11 Produce joints in the following.

Explain how to prepare the materials in readiness for the welding activity such as ensuring that the material is free from excessive surface contamination - such as rust scale paint oilgrease and moisture. A metal made from two or more combined elements. Describe the terminology used for the appropriate welding positions 12.

In this chapter some terms often used in weld design are defined. To weld a Tee-joint in the horizontal position. A cutting process in which a gas flame is used to cut metals.

Overhead positions to American Welding Society AWS and industry standards. Stick Welding Paterns. Here are the three most used welding techniquespatterns.

For Fillet welds following are the welding positions defined. The most common type of gas welding is oxyfuel welding. 407-880-4945 -------- Consulting is only available for customers FAX.

A welding process in which a gas flame is used to create the welding heat. Session time may be adjusted to accommodate. In 1G and 1F the number 1 refers to the flat position while the letter G stands for a groove weld and letter F stands for a fillet weld.

Ensuring edges to be welded are correctly prepared - such as made flat square. The 1G and 5G horizontal and 2G vertical positions refer to the pipeposition. Whipping the rod a moving it back and forth motion.

The filler metal or the weld metal is the electrode material used in the welding process. Flat PA Horizontal vertical PB Horizontal PC Vertical upwards PF Vertical downwards PG 13. Introduces the trainees to the method and procedures related to the SMAW groove welding process.

The metals to be joined are placed flat and the welder passes the electric arc over them moving across the. Select appropriate materials tools and equipment to construct metal projects to specification. The reason for using a slight motion during welding is becuse it helps spread out the weld more evenly.

A flat weld is the most basic of all welding positions. Gas welding is mainly used for repair work as well as the welding of pipes and tubes. In this position the molten metal is drawn downward into the joint.

The G stands for groove F for fillet. Also referred to as a downhand position the flat position weld is the easiest and often the first weld that new students learn. The parent metal or the base metal is the steel material which is welded.

Circles to fuse the metal in a circular motion. Horizontal Position 2G and 2F This is an out of position welding position. Trainees will learn safety procedures welding joint preparation specifications identification of physical characteristics mechanical properties and cleaning techniques of SMAW groove welds.

The result is a faster and easier weld. These are not production welding positions. 10 Describe the terminology used for the appropriate welding positions.

13 Describe the tack welding size and spacing in relationship to material thickness. Safely demonstrate Gas Tungsten Arc Welding GTAW processes in flat horizontal vertical and overhead positions to American Welding Society AWS and industry standards. Safely demonstrate Gas Tungsten Arc Welding GTAW processes in flat horizontal vertical and overhead positions to American Welding Society AWS and industry standards.

One type of material from the. The number 5 comes up when welding a pipe groove when the pipe axis is horizontal 5G and 6 when the pipe axis is inclined at a 45-degree angle 6G. A general term that applies to many kinds of welding.

Acquire and accurately use Manufacturing and Product Design sector terminology and protocols at the career and college readiness level for communicating effectively in oral written and multimedia formats. Use appropriate methods and equipment to check the quality and that all dimensional and. One of ISAs long term goals is to showcase and promote the.

Select appropriate materials tools and equipment to construct metal projects to.

What Are The 4 Basic Welding Positions And When Should You Use Them Millerwelds

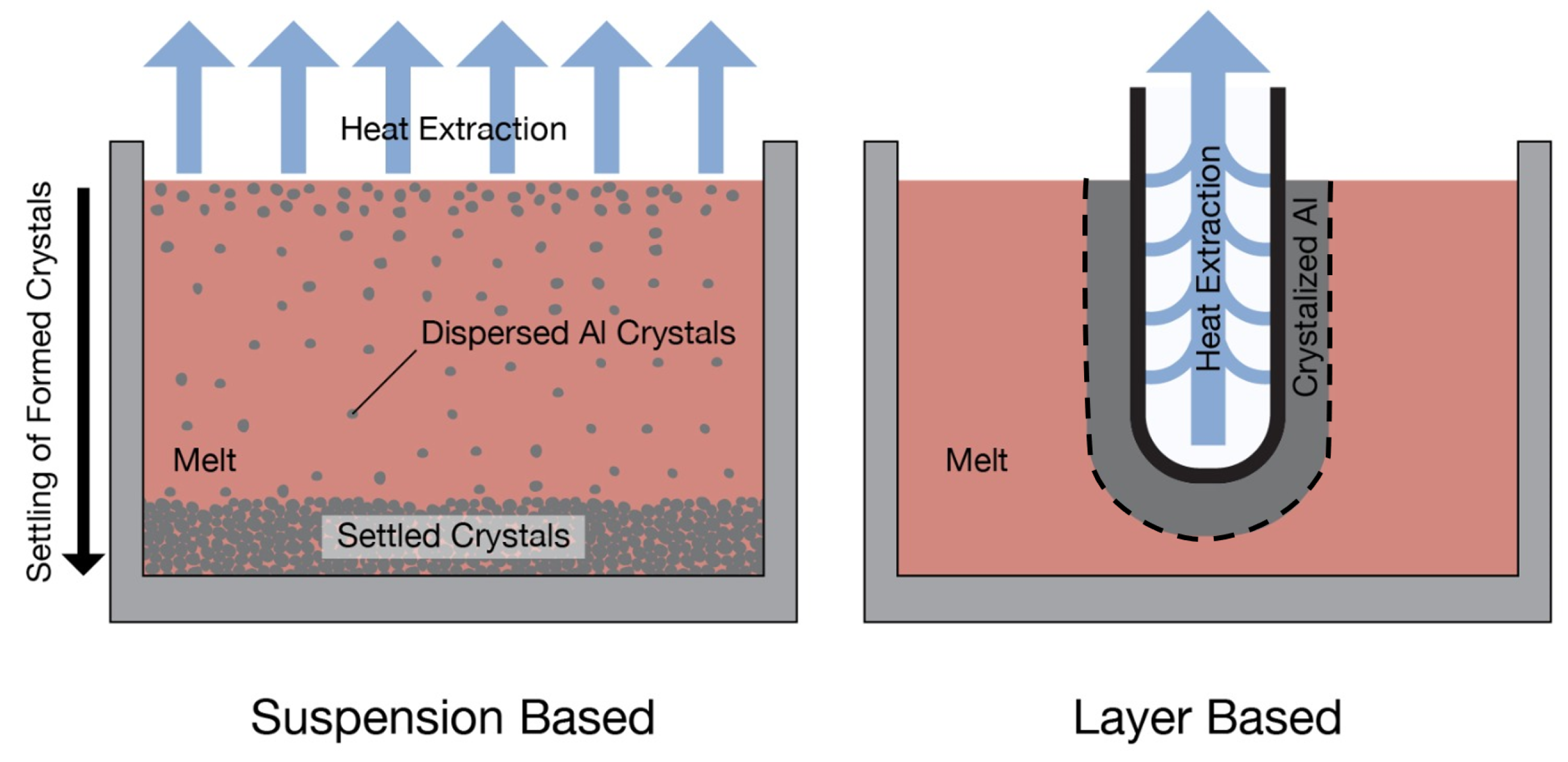

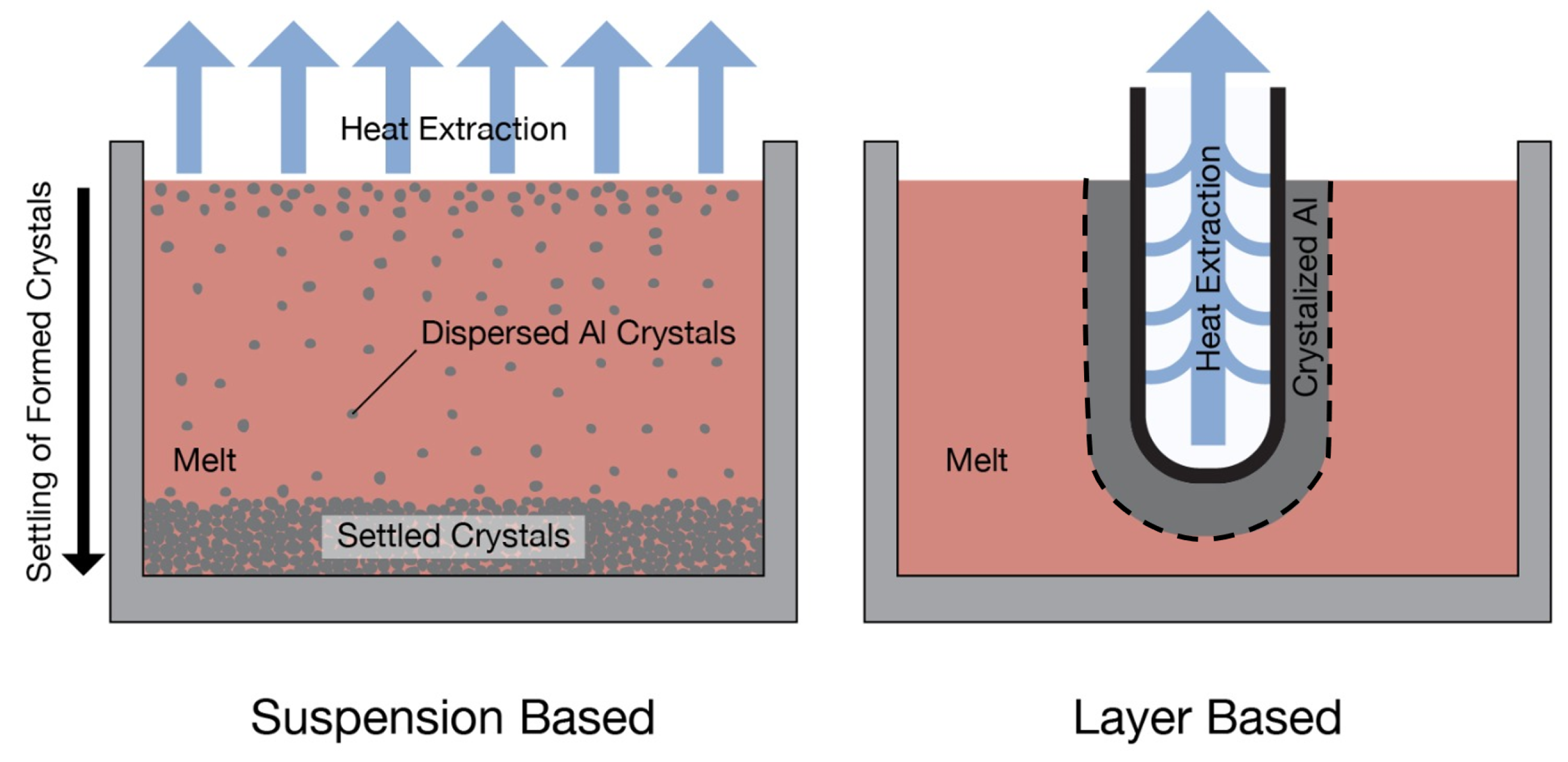

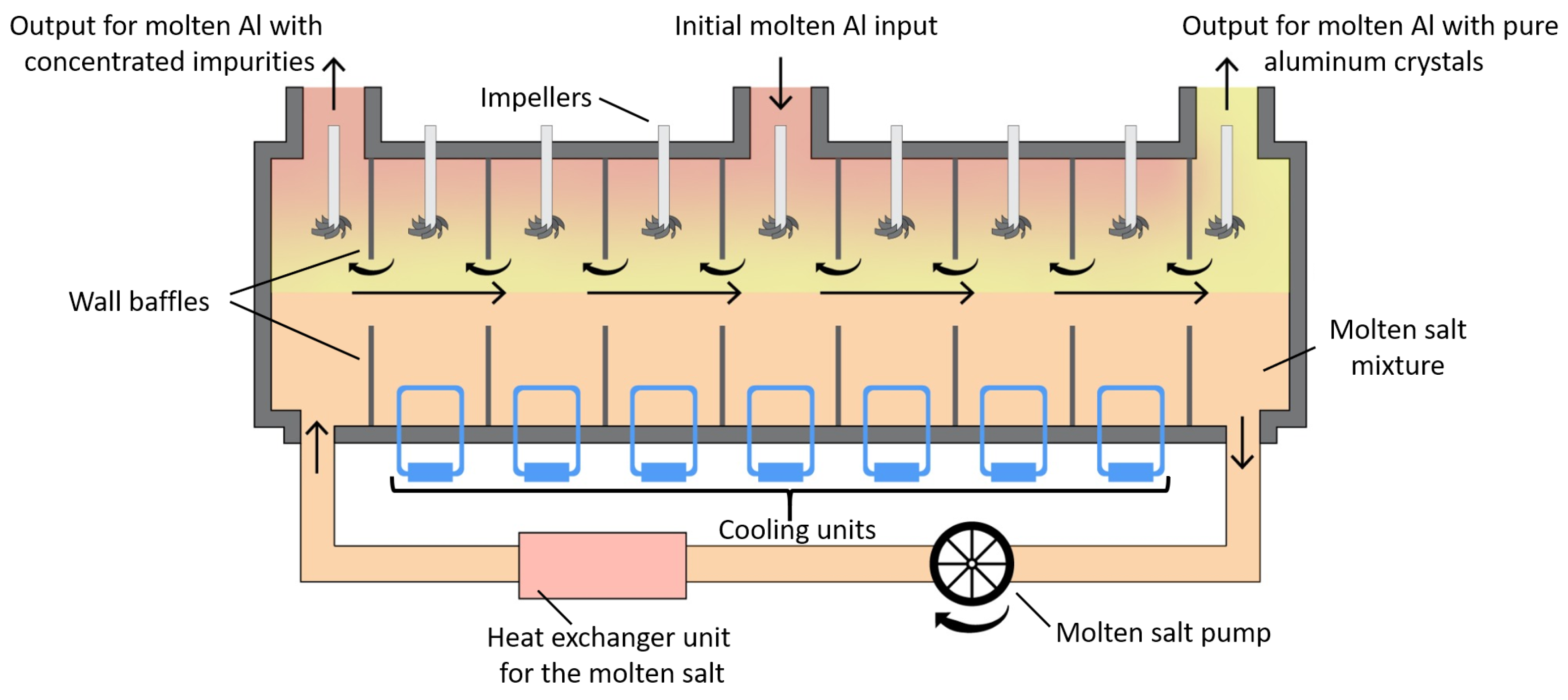

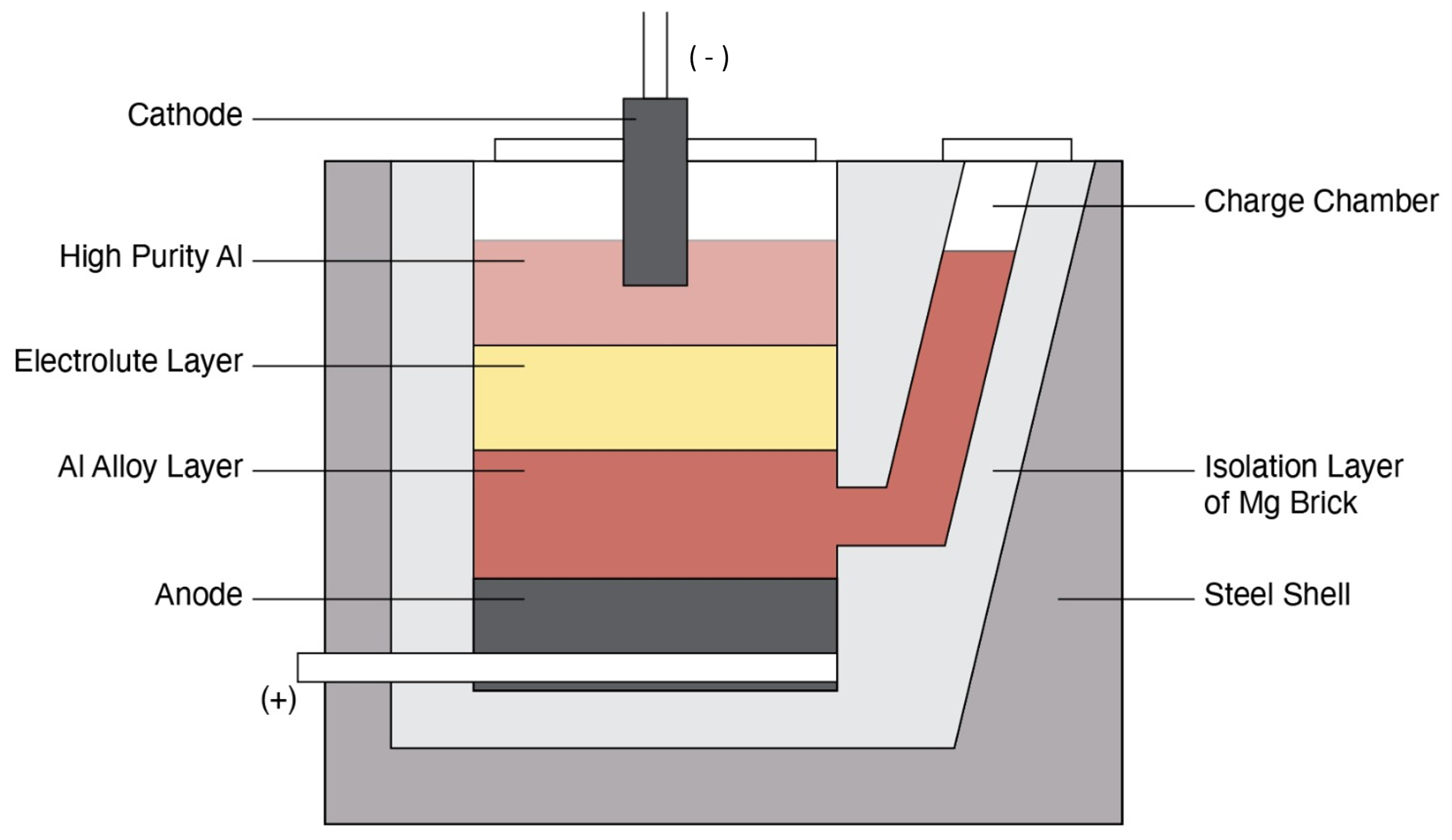

Metals Free Full Text High And Ultra High Purity Aluminum A Review On Technical Production Methodologies Html

Expanded Form To 3dp Sheet 4a Answers Expanded Form Unbelievable Facts Promote Book

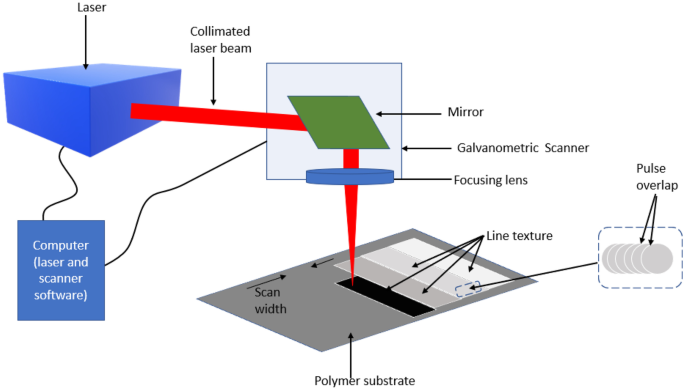

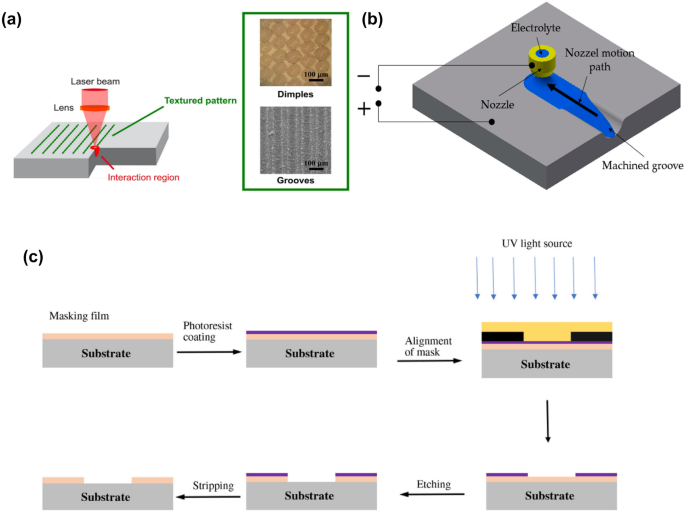

Micro Texturing Of Polymer Surfaces Using Lasers A Review Springerlink

Metals Free Full Text High And Ultra High Purity Aluminum A Review On Technical Production Methodologies Html

What Are The Different Welding Positions Tulsa Welding School

Metals Free Full Text High And Ultra High Purity Aluminum A Review On Technical Production Methodologies Html

11 Common Welding Defects And How To Prevent Them Welding Troop

What Are The 4 Basic Welding Positions And When Should You Use Them Millerwelds

Cswip 3 1 Question With Answer And Explanation Part 22 General Technical Knowledge

Sensitivity Of Hfo2 Based Rram Cells To Laser Irradiation Sciencedirect

Micro Texturing Of Polymer Surfaces Using Lasers A Review Springerlink

Modern Welding 11th Edition Page 47 47 Of 896

Metals Free Full Text Improving The Effectiveness Of The Solid Solution Strengthening Elements Mo Re Ru And W In Single Crystalline Nickel Based Superalloys Html

Types Of Welding Joints The 5 Different Types Of Welding Joints

Comments

Post a Comment